-

ㆍConventional derailleur systems rely on externally exposed components, which inherently suffer from chain drop, contamination, frequent maintenance, and reduced durability :

ATB-P fundamentally addresses these limitations by adopting a fully sealed gearbox architecture.

ㆍATB-P uses the same fixed-input 1×7 architecture as ATB-L :

The input gear between the pedal shaft and the main shaft is configured with a 54:30 ratio, increasing rotational speed while reducing the transmitted torque.

ㆍThis input structure provides several practical advantages.

ㆍFaster gear engagement :

The increased rotational speed accelerates the engagement between the pawls and the internal gear teeth, significantly reducing pedal free-play and engagement delay.

ㆍImproved shifting durability :

By reducing the torque transmitted to the main shaft and shifting components, long-term durability is naturally improved.

ㆍThe key difference from the ATB-L version lies in the use of high-strength, heat-treated alloy gears :

Thanks to the fixed input structure, ATB-P achieves durability that exceeds even that of the ATB12, despite its simpler architecture

ㆍThis enhanced durability allows the gearbox to be designed with thinner gears, enabling a lighter overall structure without compromising strength.

ATB7-P (Premium)

-

Application Advantages

ㆍDownhill bikes :

In downhill riding, the number of gears actually used is limited. ATB-P can therefore be applied as a lightweight gearbox solution while still providing exceptional durability

ㆍE-cargo bikes :

With its high mechanical strength, ATB-P pairs exceptionally well with powerful hub motors, forming a robust and reliable drivetrain for cargo applications.

ㆍThis input structure provides several practical advantages

ㆍUrban commuting :

Most urban riders do not require a wide gear range. For users who seek higher durability or a more premium feel beyond ATB-L, ATB-P offers a lightweight and reliable alternative.

ATB7-P (Premium)

ATB7-P

(Premium)

-

ATB7-P(Premium)

ㆍConventional derailleur systems rely on externally exposed components, which inherently suffer from chain drop, contamination, frequent maintenance, and reduced durability :

ATB-P fundamentally addresses these limitations by adopting a fully sealed gearbox architecture.

ㆍATB-P uses the same fixed-input 1×7 architecture as ATB-L :

The input gear between the pedal shaft and the main shaft is configured with a 54:30 ratio, increasing rotational speed while reducing the transmitted torque.

ㆍThis input structure provides several practical advantages.

ㆍFaster gear engagement :

The increased rotational speed accelerates the engagement between the pawls and the internal gear teeth, significantly reducing pedal free-play and engagement delay.

ㆍImproved shifting durability :

By reducing the torque transmitted to the main shaft and shifting components, long-term durability is naturally improved.

ㆍThe key difference from the ATB-L version lies in the use of high-strength, heat-treated alloy gears :

Thanks to the fixed input structure, ATB-P achieves durability that exceeds even that of the ATB12, despite its simpler architecture

ㆍThis enhanced durability allows the gearbox to be designed with thinner gears, enabling a lighter overall structure without compromising strength.

-

Application Advantages

ㆍDownhill bikes :

In downhill riding, the number of gears actually used is limited. ATB-P can therefore be applied as a lightweight gearbox solution while still providing exceptional durability

ㆍE-cargo bikes :

With its high mechanical strength, ATB-P pairs exceptionally well with powerful hub motors, forming a robust and reliable drivetrain for cargo applications.

ㆍThis input structure provides several practical advantages

ㆍUrban commuting :

Most urban riders do not require a wide gear range. For users who seek higher durability or a more premium feel beyond ATB-L, ATB-P offers a lightweight and reliable alternative.

-

ATB7-P(Premium)

ㆍConventional derailleur systems rely on externally exposed components, which inherently suffer from chain drop, contamination, frequent maintenance, and reduced durability :

ATB-P fundamentally addresses these limitations by adopting a fully sealed gearbox architecture.

ㆍATB-P uses the same fixed-input 1×7 architecture as ATB-L :

The input gear between the pedal shaft and the main shaft is configured with a 54:30 ratio, increasing rotational speed while reducing the transmitted torque.

ㆍThis input structure provides several practical advantages.

ㆍFaster gear engagement :

The increased rotational speed accelerates the engagement between the pawls and the internal gear teeth, significantly reducing pedal free-play and engagement delay.

ㆍImproved shifting durability :

By reducing the torque transmitted to the main shaft and shifting components, long-term durability is naturally improved.

ㆍThe key difference from the ATB-L version lies in the use of high-strength, heat-treated alloy gears :

Thanks to the fixed input structure, ATB-P achieves durability that exceeds even that of the ATB12, despite its simpler architecture

ㆍThis enhanced durability allows the gearbox to be designed with thinner gears, enabling a lighter overall structure without compromising strength.

-

Application Advantages

ㆍDownhill bikes :

In downhill riding, the number of gears actually used is limited. ATB-P can therefore be applied as a lightweight gearbox solution while still providing exceptional durability

ㆍE-cargo bikes :

With its high mechanical strength, ATB-P pairs exceptionally well with powerful hub motors, forming a robust and reliable drivetrain for cargo applications.

ㆍThis input structure provides several practical advantages

ㆍUrban commuting :

Most urban riders do not require a wide gear range. For users who seek higher durability or a more premium feel beyond ATB-L, ATB-P offers a lightweight and reliable alternative.

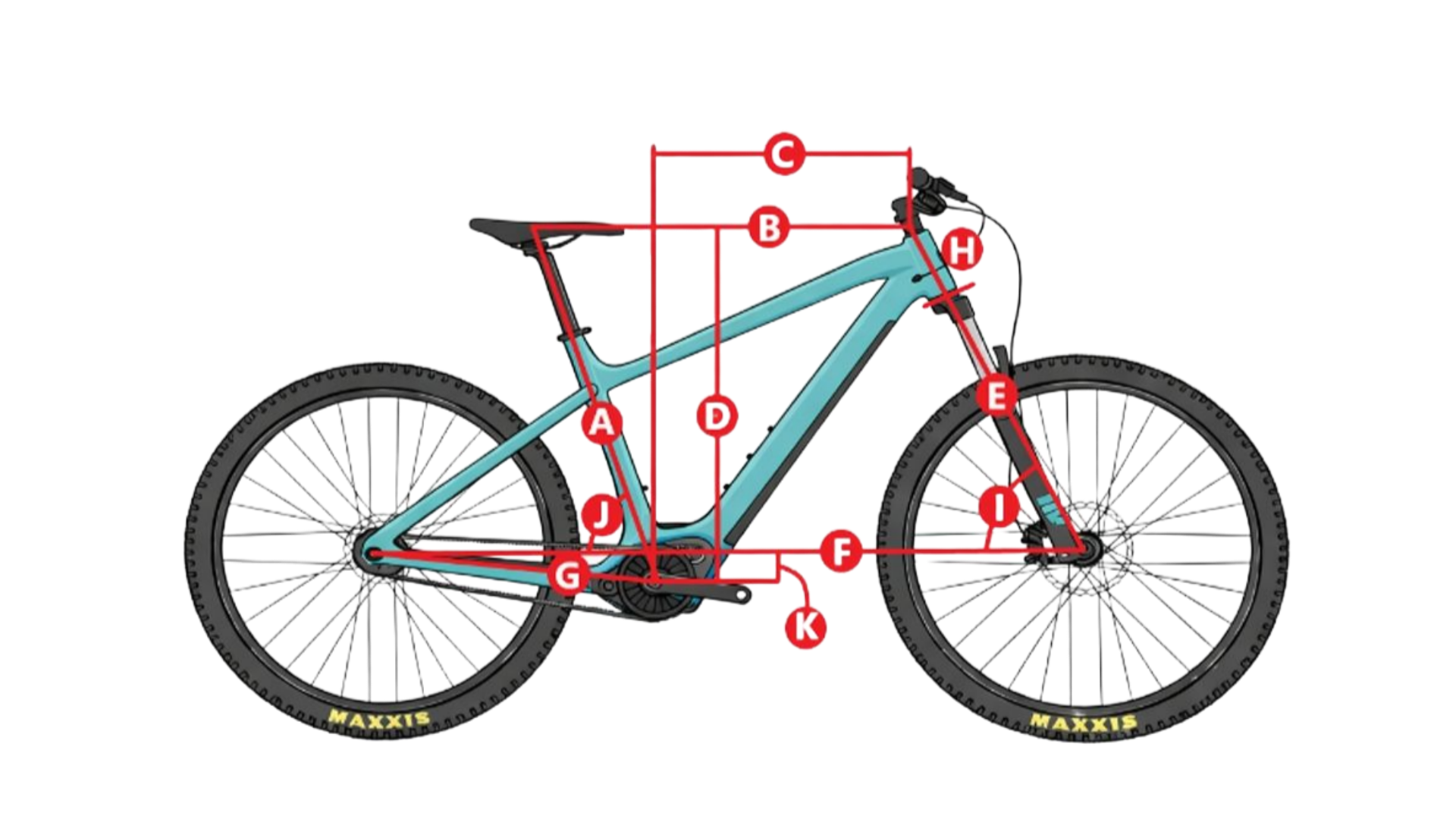

FRAME

-

ㆍA : Seat Tube Length 454mm

ㆍB : Top Tube (Effective) 600mm

ㆍC : Reach 434.1mm

ㆍD : Stack 597.2mm

ㆍE : Fork Length 480mm

ㆍF : Wheelbase 1147mm

ㆍG : Chainstay Length 445mm

ㆍH : Head Tube Length 120mm

ㆍI : Head Tube Angle 68°

ㆍJ : Seat Tube Angle 74.4°

ㆍK : BB Drop 60mm

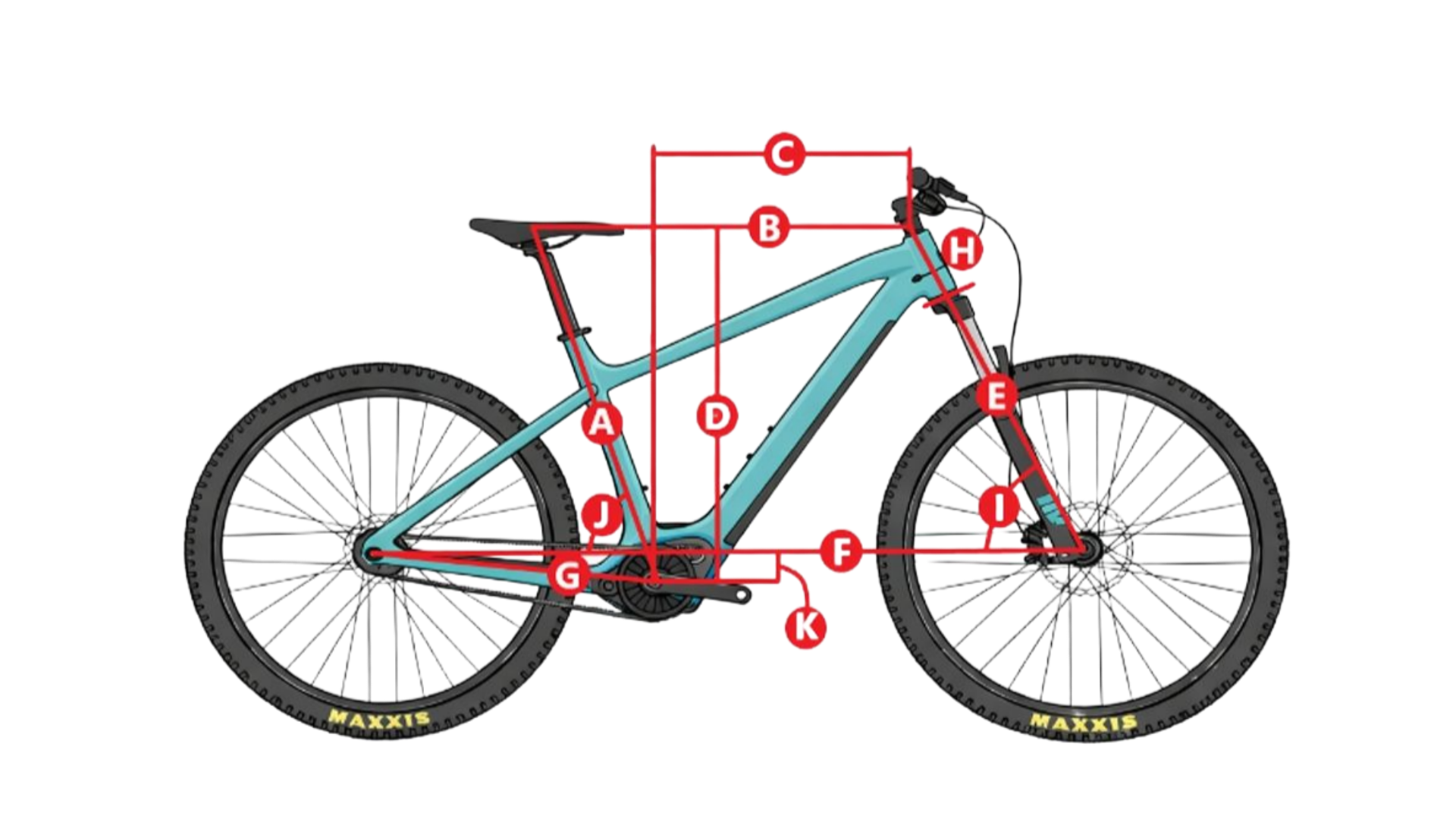

-

ㆍA : Seat Tube Length 454mm

ㆍB : Top Tube (Effective) 600mm

ㆍC : Reach 434.1mm

ㆍD : Stack 597.2mm

ㆍE : Fork Length 480mm

ㆍF : Wheelbase 1147mm

ㆍG : Chainstay Length 445mm

ㆍH : Head Tube Length 120mm

ㆍI : Head Tube Angle 68°

ㆍJ : Seat Tube Angle 74.4°

ㆍK : BB Drop 60mm

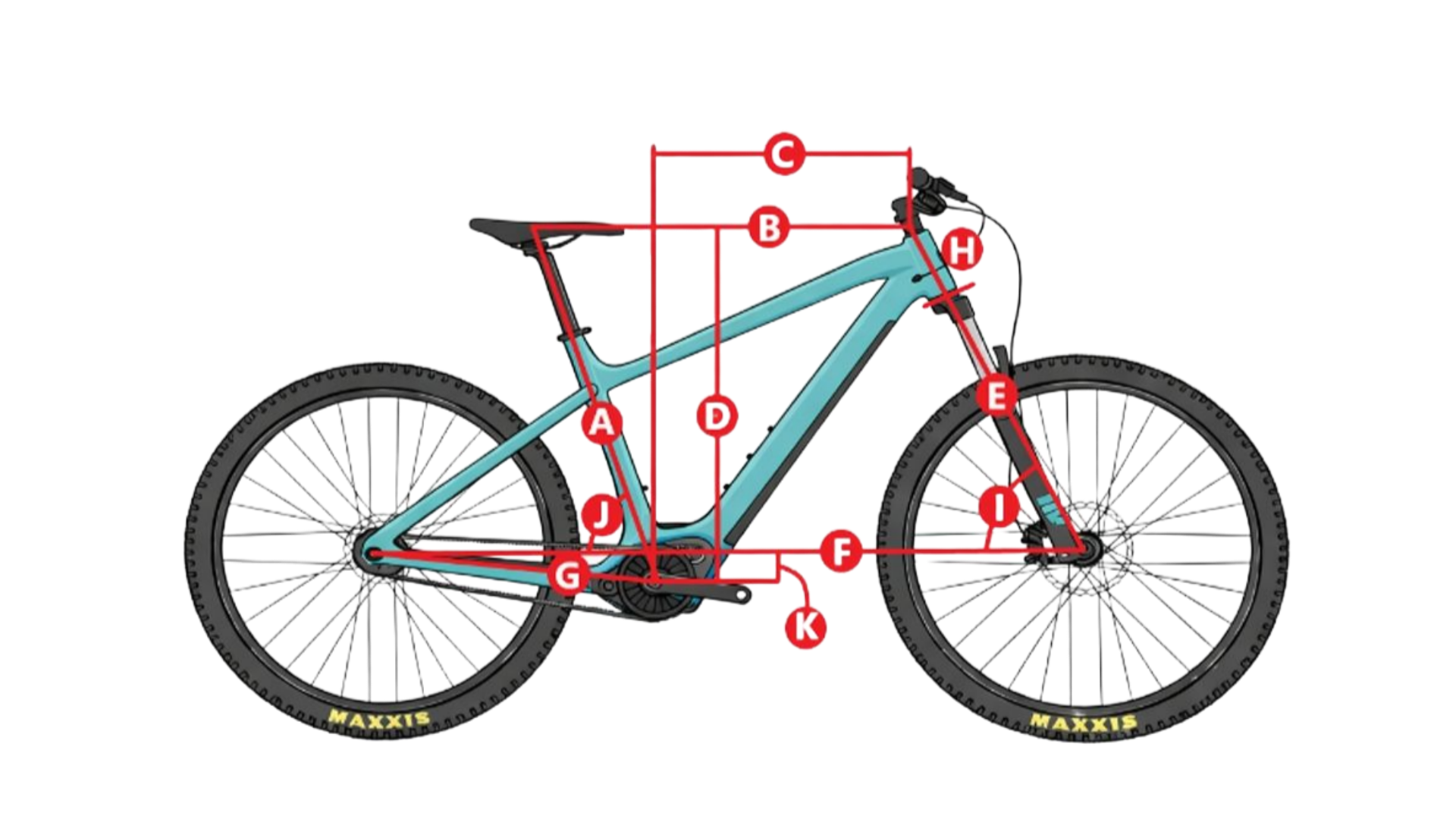

-

ㆍA : Seat Tube Length 454mm

ㆍB : Top Tube (Effective) 600mm

ㆍC : Reach 434.1mm

ㆍD : Stack 597.2mm

ㆍE : Fork Length 480mm

ㆍF : Wheelbase 1147mm

ㆍG : Chainstay Length 445mm

ㆍH : Head Tube Length 120mm

ㆍI : Head Tube Angle 68°

ㆍJ : Seat Tube Angle 74.4°

ㆍK : BB Drop 60mm

-

ATB7-P (Premium 7-Speed Gearbox)

ㆍPremium Mechanical Gearbox for OEM Testing.

ㆍThe ATB7-P is a 7-speed sealed mechanical gearboxdeveloped with a strong focus on high torque capacity, durability, and rapid OEM testing.

ㆍIt is designed as a powertrain component for development and pilot projects, enabling OEMs and brands to evaluate a gearbox within their own bicycle or e-bike systems.

ㆍThe ATB7-P can be combined with hub motors in e-bike applications, making it suitable as a test gearbox for companies developing hub-motor-based e-bikes with integrated gearboxes.

ㆍIt is also suitable for high-load environments such as downhill (DH) bicycles, where impact resistance and mechanical robustness are critical.

ㆍCompared to conventional gearboxes, its relatively lightweight designoffers a clear advantage during the development and testing phase, especially when rapid iteration and evaluation are required.

-

Key Features

ㆍ7-Speed Mechanical Gearbox :

Fully sealed structure for protection against external environments

ㆍHigh-Torque-Capable Design :

Suitable for testing in steep terrain, rough surfaces, and high-load conditions

ㆍBelt-Drive Compatible :

Enables chain-free drivetrain system evaluation

ㆍLow Maintenance, High Durability :

Ideal for repeated testing and long-term evaluation

ㆍFast Testing with ALL-TO Aluminum Frame :

A hardtail test frame that enables rapid real-world evaluation before developing a dedicated frame

-

ATB7-P

(Premium 7-Speed Gearbox)ㆍPremium Mechanical Gearbox for OEM Testing.

ㆍThe ATB7-P is a 7-speed sealed mechanical gearboxdeveloped with a strong focus on high torque capacity, durability, and rapid OEM testing.

ㆍIt is designed as a powertrain component for development and pilot projects, enabling OEMs and brands to evaluate a gearbox within their own bicycle or e-bike systems.

ㆍThe ATB7-P can be combined with hub motors in e-bike applications, making it suitable as a test gearbox for companies developing hub-motor-based e-bikes with integrated gearboxes.

ㆍIt is also suitable for high-load environments such as downhill (DH) bicycles, where impact resistance and mechanical robustness are critical.

ㆍCompared to conventional gearboxes, its relatively lightweight designoffers a clear advantage during the development and testing phase, especially when rapid iteration and evaluation are required.

-

Key Features

ㆍ7-Speed Mechanical Gearbox :

Fully sealed structure for protection against external environments

ㆍHigh-Torque-Capable Design :

Suitable for testing in steep terrain, rough surfaces, and high-load conditions

ㆍBelt-Drive Compatible :

Enables chain-free drivetrain system evaluation

ㆍLow Maintenance, High Durability :

Ideal for repeated testing and long-term evaluation

ㆍFast Testing with ALL-TO Aluminum Frame :

A hardtail test frame that enables rapid real-world evaluation before developing a dedicated frame

-

ATB7-P

(Premium 7-Speed Gearbox)ㆍPremium Mechanical Gearbox for OEM Testing.

ㆍThe ATB7-P is a 7-speed sealed mechanical gearboxdeveloped with a strong focus on high torque capacity, durability, and rapid OEM testing.

ㆍIt is designed as a powertrain component for development and pilot projects, enabling OEMs and brands to evaluate a gearbox within their own bicycle or e-bike systems.

ㆍThe ATB7-P can be combined with hub motors in e-bike applications, making it suitable as a test gearbox for companies developing hub-motor-based e-bikes with integrated gearboxes.

ㆍIt is also suitable for high-load environments such as downhill (DH) bicycles, where impact resistance and mechanical robustness are critical.

ㆍCompared to conventional gearboxes, its relatively lightweight designoffers a clear advantage during the development and testing phase, especially when rapid iteration and evaluation are required.

-

Key Features

ㆍ7-Speed Mechanical Gearbox :

Fully sealed structure for protection against external environments

ㆍHigh-Torque-Capable Design :

Suitable for testing in steep terrain, rough surfaces, and high-load conditions

ㆍBelt-Drive Compatible :

Enables chain-free drivetrain system evaluation

ㆍLow Maintenance, High Durability :

Ideal for repeated testing and long-term evaluation

ㆍFast Testing with ALL-TO Aluminum Frame :

A hardtail test frame that enables rapid real-world evaluation before developing a dedicated frame